AUMA SOLUTIONS FOR THE SHIPBUILDING INDUSTRY

AUMA has been established as one of the leading manufacturers of electric actuators for more than 60 years. We have been supplying actuators and solutions for the military and civil shipbuilding industry for more than 40 years. All product generations are compatible. Safety at its best.

AUMA actuators and controls are designed to withstand hostile environmental conditions with long lifetimes. Premium quality standards warrant reliability and maximum availability.

- Maximum control flexibility

- No additional operation media such as compressed air and hydraulic oil required

- Ensuring robust and reliable operation of existing systems

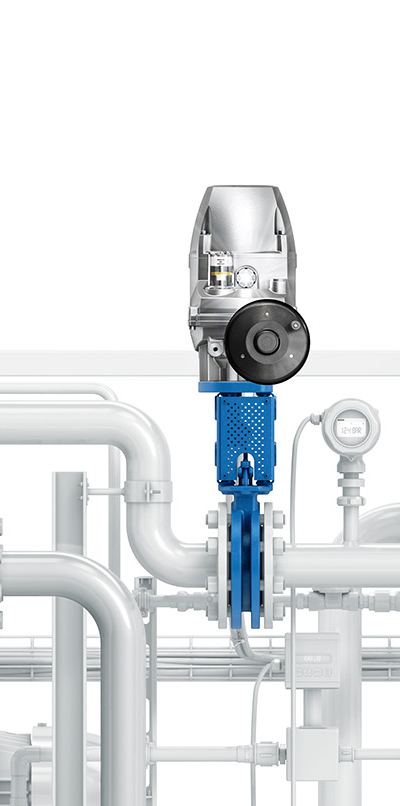

PROFOX PLATFORM

Electric actuators for ball and plug valves, butterfly valves, gate valves, globe valves and special applications.

properties

IP 68

Ex h tb IIIC T130°C Db

DEKRA 21ATEX0092 X

&

IECEx DEK 21.0058X

Discover the new PROFOX in 360°

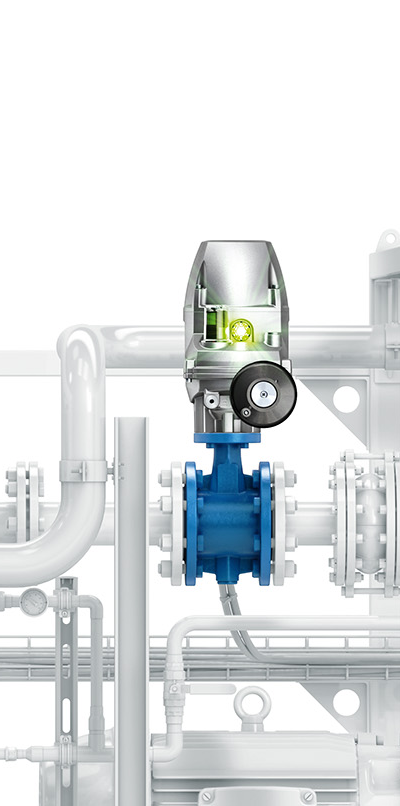

The position indicator signals the valve position through its rotating indication. During commissioning, the position indicator must be adjusted to the valve position. For the part-turn actuator type, three versions are available for different swing angles or swing angle ranges: 90°, 120° and 45° through 360°. The indication rotates in horizontal direction. For the multi-turn actuator type, the valve position is shown in vertical direction with up to max. 27 turns per stroke. The display travels vertically.

The actuator is equipped with a handwheel to ensure manual operation or emergency operation. On request, the actuator can be supplied without handwheel function.

PROFOX has a modular platform concept. The output drive housing with the integrated combination of spur wheel and planetary gearing varies depending on the speed and type of motion. PROFOX is already available as part-turn and multi-turn actuator. The linear actuator version will follow at a later stage.

As standard, PROFOX is equipped with electronics for motor control and basic communication to the DCS. Two additional slots are available for inserting further boards, e.g. to allow communication via fieldbus. Boards for Ethernet protocols as well a a board with additional I/O contacts are planned. A firmware update is possible using the USB port.

PROFOX allows local end position setting using four push buttons. The LED located left of the push buttons indicates the respective status.

- End position OPEN is set once the LED is illuminated in green.

- Operation into end position OPEN is indicated when the LED is blinking in green.

- End position setting is possible once the LED is blinking in blue.

- End position CLOSED is set once the LED is illuminated in red.

- Operation into end position CLOSED is indicated when the LED is blinking in red

Different colours and lighting patters (blinking/flashing, illumination) are used for the FOX-EYE indication light to signal operation direction, end position, functionality or faults.

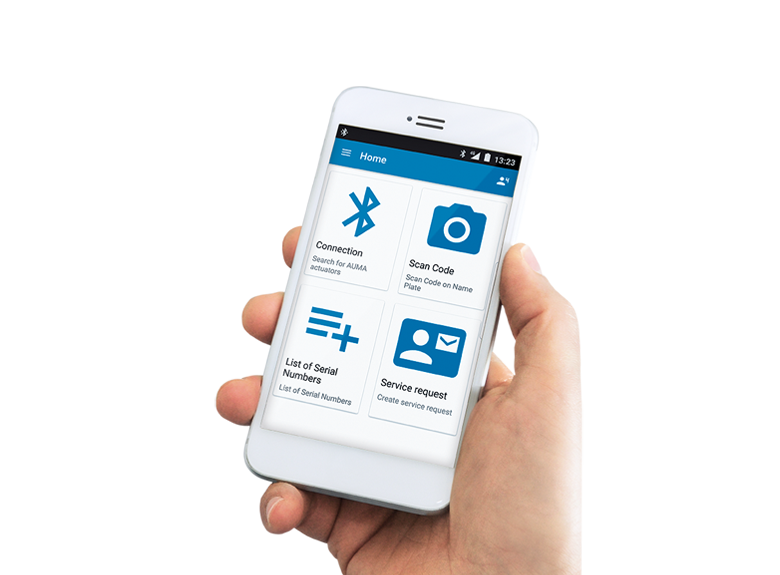

PROFOX operation is comfortable via smartphone or AUMA Assistant App (for Android devices) or via the AUMA CDT software (Diagnostics & Commissioning Tool in the latest version) via notebook or tablet. All parameters for configuration can be read and modified using the App. The selected user level determines which parameters can be changed by the user. Furthermore, diagnostic information and operational data of the actuator can be downloaded and displayed.

CORALINK provides support in all phases of the product lifecycle.

AUMA CDT

The AUMA Commissioning and Diagnostic Tool (CDT) is a proven and long-standing software tool for

configuration of AUMA actuators and effectively record diagnostic data.

- Configure, analyse and compare parameters

- Motor analysis like uptime, maximum starts per hour and running time

- Assess characteristics to detect high strain and prevent wear

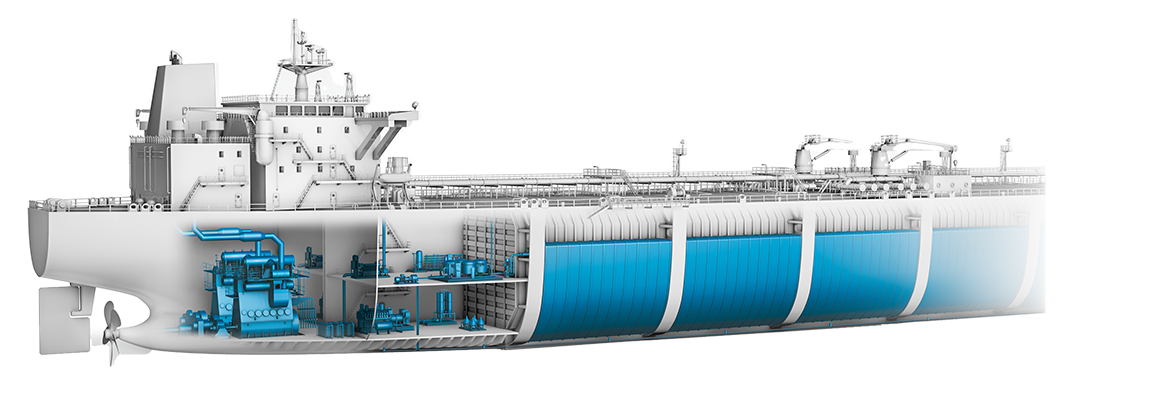

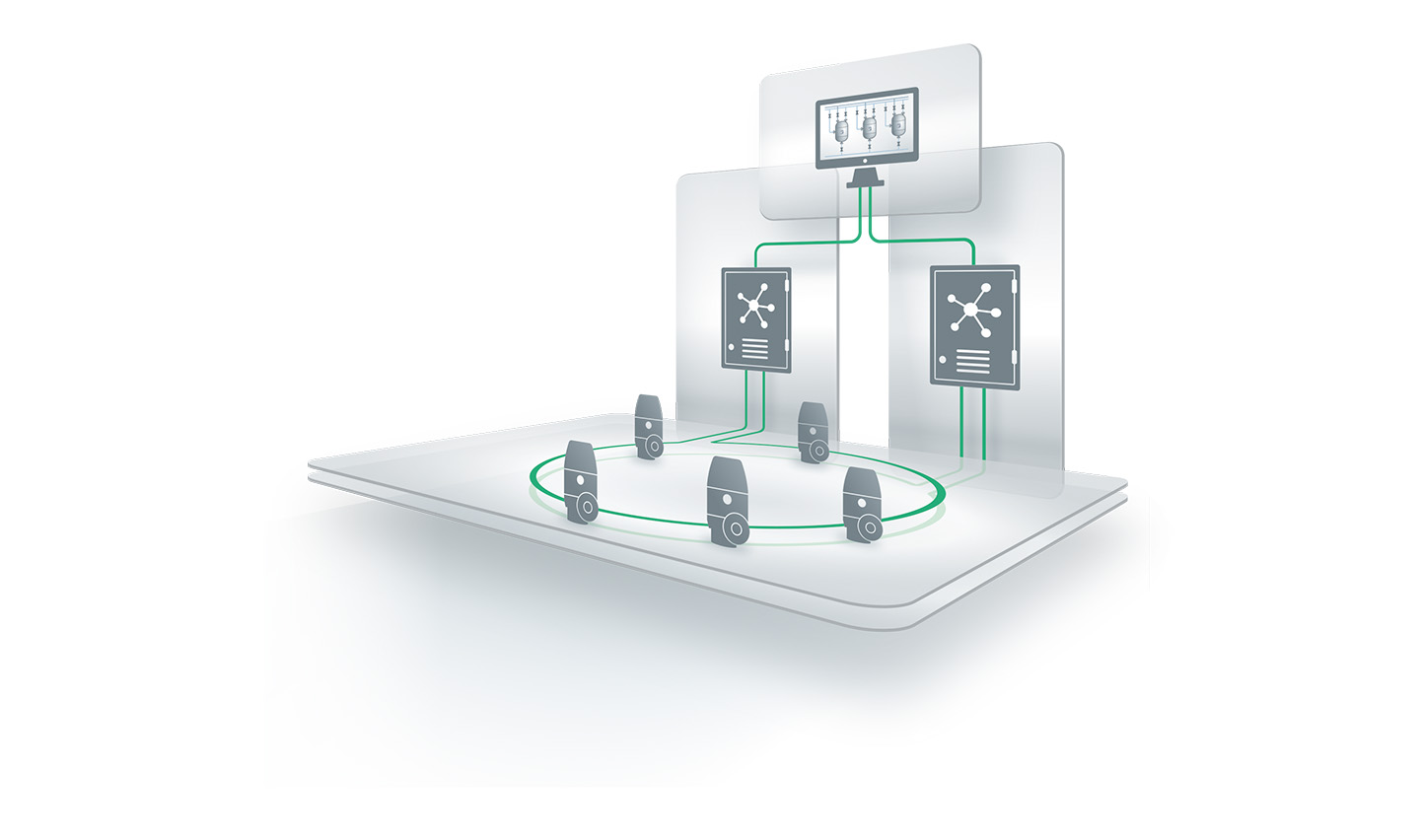

VALVE REMOTE CONTROL SYSTEM (VRCS)

Motorised valve systems with electric operation are increasingly deployed in vessels. Fieldbus technology in particular gains wider importance and offers many benefits and options:

- Implementation of new and modern communication protocols

- High data transmission rates and valuable information about actuators and motor operated

- valves (MOV)

- Live operating data and system diagnostics

- Remote monitoring for digital twin function

- Low installation cost

- Low installation time

- Standardised fieldbus systems

VRCS BY AUMA

Supports IMO requirements for Safe Return to Port (SRtP)

Potential for enhancement at any time

Power supply, fieldbus, communication and control cabinets of the VRCS designed as two separate units

Allows for intelligent and predictive maintenance leading to maximum plant availability

Loop, daisy-chain and point-to-point configuration possible

SAFE RETURN TO PORT

The regulations for the Safe Return to Port (SRtP) are firmly established within the worldwide applicable SOLAS convention, IMO decision MSC.216(82):

- System redundancies

- Safeguarding the functions of vital systems after an accident

- Safe closing of all hull valves

The AUMA portfolio facilitates the implementation of the regulations and achieves the objective of increasing the safety of passengers, the crew and the vessel.

The cooperation with AUMA

- Provides valve automation in compliance with submitted specifications

- Assures safety for design and implementation for the consultant on the basis of certified interfaces

- Guarantees the plant operator maximum availability by a global local service assisting during commissioning and providing product training

- Offers customer-specific solutions like linking MOVs (VRCS) in compliance with the rules of SOLAS as well as provision of actuator data for the digital twin or Industry 4.0.

AUMA Riester GmbH & Co. KG

Daimler Str. 9

73747 Ostfildern

| +49 711-34803-0 | |

| Sales.Marine@auma.com |