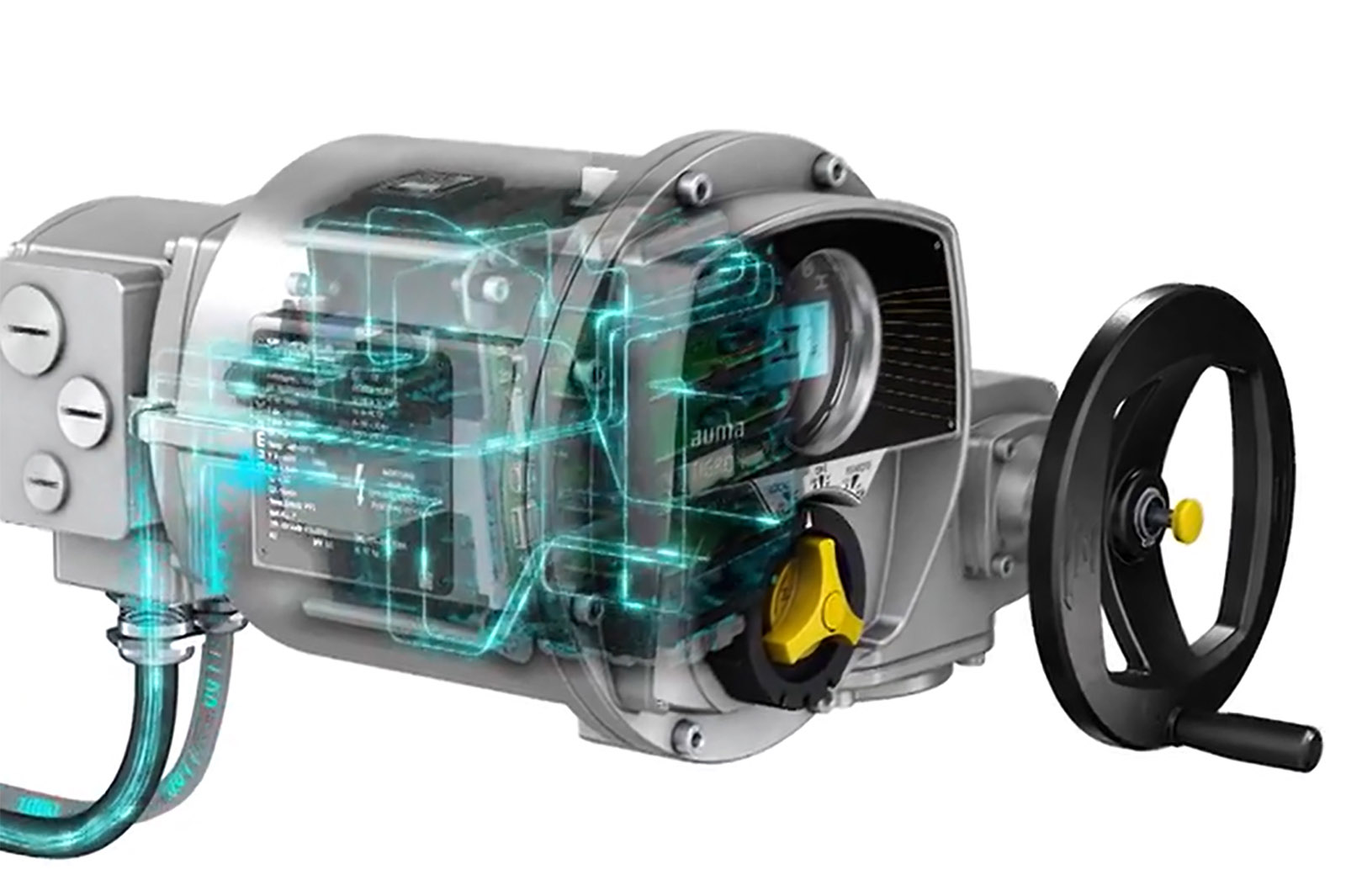

True networkers

AUMA actuators assume key functions in process control. Functional reliability is imperative for smooth plant operation.

- Integral intelligence, sophisticated sensors and comprehensive data logging support you in securing the availability of your actuators.

- Actuators can be linked in networks and have a variety of interfaces to the DCS, the AUMA Cloud and further systems.

Data, data and again data

A sound data basis is the precondition for successful digitisation. AUMA actuators are equipped with comprehensive sensors. They automatically record a multitude of meaningful operational and device data such as number of starts, motor running time, temperatures as well as a time-stamped event report.

Outstanding connectivity

Local read function

Just read all data from your actuator via Bluetooth, using either the AUMA Assitant App or AUMA CDT.

Simple data transfer

Powerful standardised interfaces enable simple data transfer to superordinate systems, e.g. via Industrial Ethernet (Profinet, Modbus TCP/IP, EtherNet/IP), fieldbus (Profibus DP, Modbus RTU), HART or WirelessHART.

SIMA² Master Station

Use our flexible control system as edge gateway. Convert e.g. Modbus RTU into Modbus TCP/IP if actuator data recorded locally using highly efficient and redundant fieldbus systems is to be transmitted as IP-based information across long distances.